HEALTHCARE SECTOR COUNTS ON VISA BACKUP SYSTEM FOR RELIABLE POWER

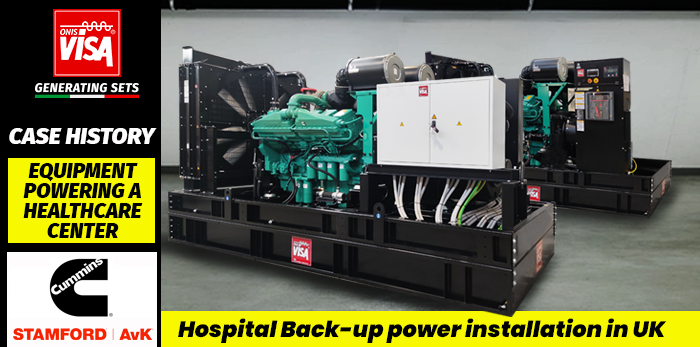

Visa SpA has supplied 2 units of generating sets of 1000 kVA each, open version, to a site in UK to provide emergency power to a clinical site facility.

The main challenge was to provide an effective power supply system in a sector where, if power drops out from the local grid, the problem needs to be solved instantaneously with a switch to standby system. Robust and efficient stand-by power plays an important role, in fact, for a healthcare structure where a reliable power supply is nothing short of a lifesaver to keep all functions properly running and always on such as departments and operating rooms, intensive care units, diagnostics and laboratories, special heating and ventilation requirements, services, lifts, fire detection system and son on.

A special project has been developed by our technical department in cooperating with Visa distributor on site to meet all requirements and to grant the security of a constant supply of the energy necessary for all the processes of the structure.

| DATA | DESCRIPTION |

|---|---|

| Project: | EQUIPMENT SUPPLIED TO A HEALTHCARE STRUCTURE |

| Location: | UK |

| Power installed: | 2 MW (P.R.P.) |

| Generating sets supplied: | 2 units of genset model C 1000 U |

Video:

Purpose:

The project involves a reliable electricity supply system in emergency mode for the operational functionality of a hospital installation. Considering the critical nature of the application, machines have been designed to ensure efficiency and maximum safety.

Technical specifications:

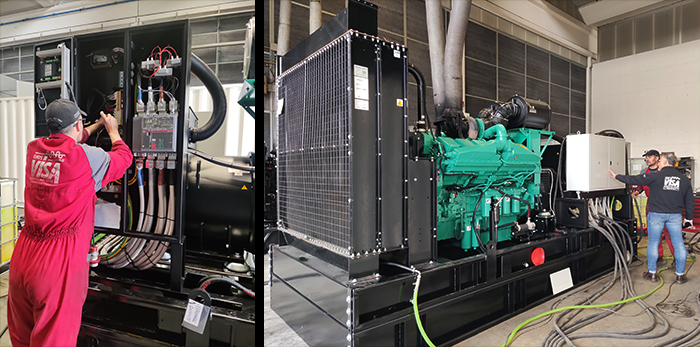

Both generating sets have been fitted with a Cummins diesel engine model KTA38-G14, 1500 rpm, selected for its high performance and quality, including engine preheater, and Stamford alternator model S6L1D-E, guaranteeing reliability and cutting-edge technology, crucial aspects to avoid any risks arising from the power failure of infrastructure.

Control panel:

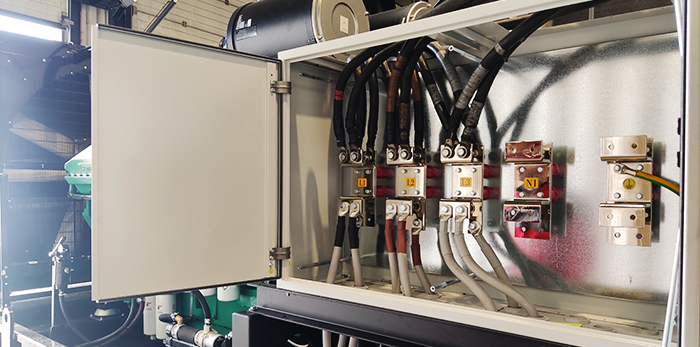

The two generating sets are equipped with terminal board PW 005 for control and auxiliary circuits and provided with a 3200A Powerlink Box, a specific feature in accordance to the customer’s requirement, realized with the power cables outlet in the top side. Both units are equipped with a control unit only for a fast start-test that is removed before the final installation.

Fuel tank:

Under the baseframe, the two generators mount a removable 2100 Lt. oversized fuel-tank, complete with retention basin and fuel leak sensor, to provide appropriate fuel autonomy operation. The removable tank allows the genset to enter the small-sized room as per customer’s requirement. Once on site, the fuel-tank is assembled again. Moreover, the fuel tank is provided with lifting points and technical documentation to support the installer during the handling and the installation, a necessary condition to grant a good and complete product.

Baseframe:

Thanks to its structural design and anti-vibration mounts placed between engine-alternator and the baseframe, the strong baseframe reduces the vibration level to minimum. It has been designed to allow the fixing of the customized 2100 Lt fuel tank in the lower part.

Other features of the plant:

The hospital required the machines in open version to be compact enough to fit inside a specific technical room. In order to fulfil this strict requirement, the units were partially disassembled to be moved into the room and mounted again with accessories once they were placed on site. All the installation process was carefully followed step by step by our distributor’s staff and highly qualified technicians.

A key performance feature that attracted the customer to the brand was also the technical support and assistance assured by the local official distributor.

Test:

All Onis Visa products are always subject to a strict operating test involving over 30 checks prior to delivery (the standard FAT, Factory Acceptance Test). For this project in particular, the customer required an additional FAT procedure. In this case, a 4-hour uninterrupted test with different loads was requested as follow: 1 hour at 50%, 1 hour at 75%, 1 hour at 100% and 1 hour at 110%. The special complete test was performed by our engineering staff at the factory prior to the delivery. Since the customer could not be present, the entire procedure was carried out online, to be sure that, when the system arrived at destination, it would be running smoothly and fully complying with the customer’s specifications. Both the technical and the marketing department of VISA SPA, coordinated by the project manager, have been involved to carry out the tests and the video recording of the whole process to comply with the client’s needs. The cooperation among different resources of the company in strategic work represents one of Visa strength.

Visa SpA stands out because of its high-quality products and expertise in power generation developed in more than 60 years of constant presence in the market providing specific products developed for healthcare sector and offering innovative technology and the most convenient and reliable solutions.