Visa genset powers a multi-storey service centre

Visa SpA has successfully supplied one unit of special-version generating set for a management and service center in a coastal area in Ireland, destined to a new 10-storey building, used as management and service center to ensure uninterrupted operations and safety even during possible power failures.

Having a backup generating set in the building is crucial for ensuring uninterrupted operations and safety complying with regulations. It allows essential systems like lighting, elevators, security, and communication to remain functional during power outages, minimizing downtime and maintaining productivity.

DATA DESCRIPTION

Project: Equipment supplied for a service center

Location: Coastal area in Ireland

Power installed : 400 kVA (PRP)

Generating sets supplied : 1 unit mod. BD 400 GX in special version. Continuous power (P.R.P.) kVA 400.0, Stand-by power (L.T.P.) kVA 440.0

Purpose:

This project is planned to assure a reliable emergency electricity supply system tailored to meet the needs of a multi-storey building. The unit will be positioned in the basement of the structure. A specifically engineered remote cooling kit will replace the standard radiator and transfer the heat to be dissipated to a dry cooler positioned at a height of approx. 50 mt. above the engine. The genset has been meticulously designed to deliver optimal efficiency in all circumstances, mitigating risks, upholding efficiency, and ensuring uninterrupted operations.

Special configuration:

Given the nature of the application, the specific site requirements as well as the saline environment, a specially tailored genset was chosen. This customized unit boasts several key features, including a remote radiator, a cooling kit designed to fit the exact needs of the site with features like an overpressure valve and bypass, as well as an integrated pump. To accommodate the limited space within the installation room, a special canopy was provided for the machine.

Technical specifications

The gen set has been fitted with Baudouin engine model 6M21G440/5, 1500 rpm, complete with engine preheater and Stamford alternator model S4L1D-F in H class. The unit mounts an automatic control panel, in silent version.

Control panel

The genset is equipped with the advanced InteliLite 4 AMF automatic control panel, which serves as a sophisticated controller. It is user-friendly and adaptable providing numerous configuration choices and resulting an optimal solution for generator control and monitoring.

Remote annunciator

A separate control room houses a remote annunciator, which is connected to the genset via Can Bus. This remote annunciator utilizes LEDs to provide instant visual feedback on the status of the genset, promptly indicating any potential warnings or alarms.

Remote cooling kit and dry cooler

Given that the electricity generator will be installed in the basement of a ten-storey building, an efficient cooling system is essential for the project. To address this requirement, a specially designed cooling kit will be installed instead of the standard radiator. As part of the cooling system, a dry cooler will be positioned at a height of approximately 50 meters on the roof, employed to dissipate the heat generated by the engine.

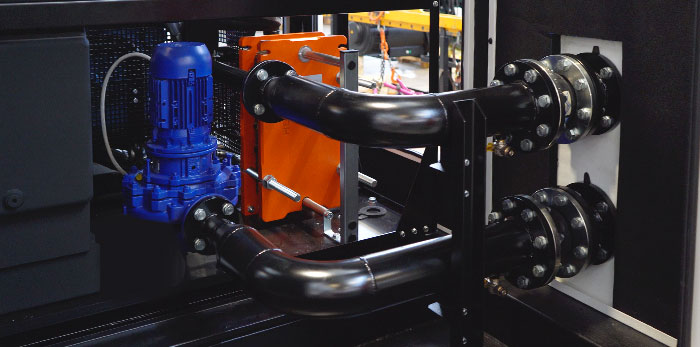

The cooling kit consists of two main components: a plate heat exchanger for cooling the engine water jacket and an air-to-water exchanger for cooling the charged air.

In this project, the customer has requested that our engineering team integrate the circulation pump within the cooling kit. The pump has been appropriately sized to facilitate the movement of coolant from the secondary side of the kit up to the roof.

To ensure safety, a relief valve is included in the system. In the event of excessive pressure, the relief valve allows the coolant to flow through a bypass circuit, preventing any damage to the exchangers.

Due to the installation site being in a coastal area, the frame of the dry cooler undergoes a C5M painting cycle to safeguard it against the corrosive effects of the saline environment.

The engine compartment is cooled effectively by the installation of a cooling fan within the canopy.

Fuel polishing system

On customer’s request, we will install in the genset a fuel polishing module. In the case the genset remains inactive for an extended period in fact, the module ensures that the diesel fuel stored in the tank remains protected from detrimental contaminants.

Canopy

The customer has dedicated a machine room in the building’s basement specifically designed to house the generating set, equipped with all the necessary features to ensure its optimal functionality.

For this project, an oversized canopy has been chosen, with an integrated 950-liter fuel tank. Considering the limited space available in the installation room, the customer requested our assistance in designing the canopy with bayonet mounted doors. Additionally, the genset canopy features two flanges that enable the connection of hot and cold coolant lines, which will be directed towards the dry cooler.

Since the original radiator’s fan has been removed, the cooling of the engine compartment is granted by a fan installed on the genset canopy.

Conclusion

The customer chose Visa for its highly reliable machines that provide uninterrupted power supply during critical situations. Visa gensets are built to withstand demanding conditions, ensuring durability and safety. By incorporating advanced technologies and engineering expertise, Visa generators offer efficient performance and optimized fuel consumption, resulting in long-term energy and cost savings.